OIML BULLETIN - VOLUME LXVI - NUMBER 2 - April 2025

e v o l u t i o n

Mastering EMC compliance in legal metrology:

A guide to conformity assessment & best practices

Maurice Mergler

Citation: M. Mergler 2025 OIML Bulletin LXVI(2) 20250201

Introduction

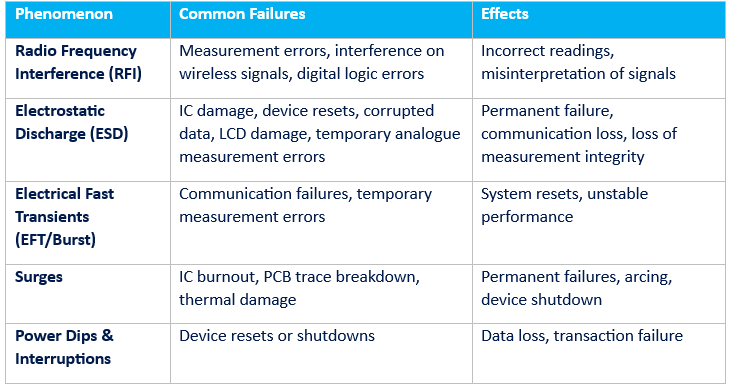

Ensuring accurate and reliable measurements is essential to fair trade. Whether weighing produce in a supermarket, dispensing fuel at a gas station, or calculating electricity consumption in a home, measurement devices must maintain precision despite the electromagnetic noise present in everyday environments. Yet, as electronic systems become more complex and interconnected, they are increasingly vulnerable to electromagnetic interference (EMI). These phenomena can disrupt measurement accuracy, cause transaction errors, and lead to financial loss or regulatory non-compliance.

Real-world examples illustrate the consequences of EMI in legal metrology:

- A weighing scale could fluctuate when a nearby mobile phone receives a call, leading to an incorrect transaction.

- A taximeter could register an inflated fare when the driver presses a button and unintentionally triggers an electrostatic discharge.

- A flowmeter measuring crude oil could deviate because of interference from a nearby radio transmitter.

- LED lighting could cause disturbances on power lines, making an electricity meter register higher consumption than actual use.

To prevent such issues, the International Organization of Legal Metrology (OIML) requires Electromagnetic Compatibility (EMC) immunity testing for measurement devices used in trade . These tests ensure that instruments continue to function correctly despite exposure to radio frequency interference (RFI), transient electrical disturbances, electrostatic discharges (ESD), and power surges. Unlike general EMC testing, which evaluates a device’s overall electromagnetic emissions and susceptibility, OIML focuses specifically on measurement accuracy in the presence of EMI.

Yet, despite well-established testing frameworks, many manufacturers fail EMC testing due to design flaws, insufficient shielding, and a lack of pre-compliance testing. Such failures result in costly redesigns, delays in market entry, and compliance roadblocks. Understanding the root causes of EMC failures and applying best practices early in the design process can help manufacturers avoid these setbacks and ensure regulatory approval.

This article explores common EMC failures in legal metrology devices, key engineering best practices, and strategies for effective conformity assessment under OIML requirements.

Common EMC failures in regulated measuring devices

Different types of measuring instruments react differently to electromagnetic disturbances. The impact depends on the device's nature, the surrounding electromagnetic environment, and how well the device is shielded. Understanding these vulnerabilities is the first step toward compliance.

Weighing scales

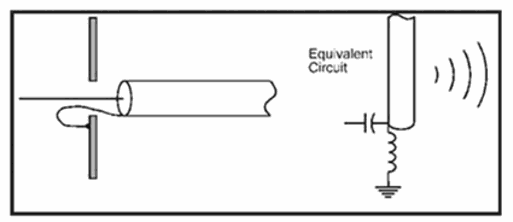

Weighing instruments rely on sensitive analogue-to-digital (A/D) conversion to measure weight accurately. When exposed to EMI, the A/D converter can pick up unwanted signals, causing fluctuations in weight readings. For instance, radio frequency signals can be demodulated within the converter, introducing noise that results in incorrect outputs.

Other common issues include communication failures between internal components due to signal interference and display flickering when pulsed disturbances disrupt display drivers. Electrostatic discharge and power surges can also damage integrated circuits, leading to permanent malfunctions.

Pulse counting devices (water meters, fuel dispensers, flow meters)

Devices that rely on pulse-based counting mechanisms are particularly vulnerable to EMI. Electrical transients—such as burst pulses, ESD, or power surges—can be mistakenly interpreted as valid pulses, leading to incorrect flow measurements. This is especially problematic in fuel dispensing, where an erroneous pulse count can result in overbilling or underbilling.

Current and voltage measurement devices (kWh meters, EV chargers)

Energy meters and charging stations are susceptible to EMI from power lines or industrial equipment, which can distort voltage and current readings. Conducted RF disturbances and harmonics generated by nearby machinery can alter the waveform detected by the meter, leading to miscalculations in energy consumption. This can result in incorrect billing, disputes, and potential regulatory action.

Understanding these failure modes allows engineers to develop strategies to design for compliance rather than react to failures later in the development cycle.

Best practice for EMC compliance

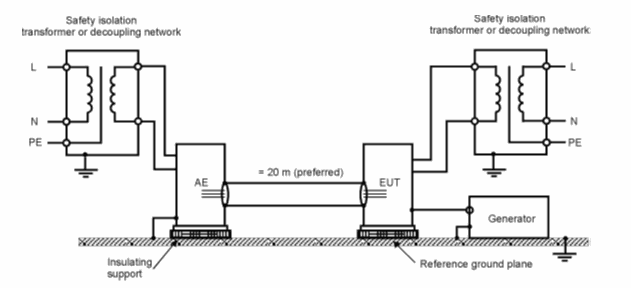

Addressing EMC risks early in the design phase is the most effective way to ensure compliance. Implementing robust printed circuit board (PCB) design, shielding techniques, and pre-compliance testing can significantly improve a device’s immunity to electromagnetic disturbances.

Designing for EMC from the start

A well-designed PCB can significantly improve EMC performance. Engineers should use solid ground planes to minimize noise coupling, route high-frequency signals close to a ground reference, and keep power and ground traces wide and close together. Sensitive analogue circuits, such as A/D converters, should be shielded from high-frequency digital lines when necessary.

Grounded guard loops around sensitive signal lines can reduce noise pickup.

Component selection is also critical. Opting for low-EMI components and ensuring proper decoupling with capacitors can prevent unnecessary emissions and improve immunity. Surface-mount components generally perform better than through-hole alternatives due to shorter lead lengths and reduced susceptibility to radiated EMI.

Shielding and grounding strategies

Shielding is essential for protecting a device from external interference. Metal enclosures should be electrically bonded to prevent RF leakage, and cables should be shielded at entry points using a 360-degree metal gland to decouple unwanted signals to ground. Proper connection of your shielding is essential.

Good grounding practices ensure that electromagnetic disturbances are safely dissipated rather than coupled into sensitive circuitry. while bonding straps maintain ground continuity in enclosures with moving parts.

Filtering and surge protection

Many EMI issues arise from disturbances entering a device through its power lines. Proper filtering at the power input—using ferrite beads, common-mode chokes, and transient voltage suppression (TVS) diodes—can prevent conducted noise from affecting performance. In surge-prone environments, additional metal oxide varistors (MOVs) can help absorb high-energy pulses before they damage critical components.

ESD protection

Placement of your most sensitive parts is extremely critical. Too close to a metal housing can cause sparks from the discharge during ESD-testing directly to your PCB or in case of a plastic housing, air discharges easier bridge the gap between exterior and your PCB.

Manufacturers should closely consider the discharge path for applied ESD. A common method is to bring chassis ground on a circuit board ground back to the main power input. This allows any discharges to dissipate without affecting the rest of the circuitry.

Power lines

Many instruments are powered by AC/DC adapters. It pays off to invest in better quality adapters from a trusted manufacturer. Requesting a test report from the manufacturer is always a good idea. Many manufacturers will provide test reports to support their claims about their equipment.

Pre-compliance testing: Detecting issues early

Many manufacturers fail formal EMC testing because they skip pre-compliance testing during development. In-house EMC testing using ESD guns, burst generators, and RF immunity setups can help identify potential failures before formal certification. Simulating real-world EMI conditions ensures that vulnerabilities are addressed early, reducing the risk of costly redesigns.

Preparing for OIML conformity assessment

To streamline the approval process, manufacturers should follow a structured approach to EMC compliance:

- Understand applicable standards. Research OIML EMC immunity requirements as well as any regional emissions regulations, such as the European EMC Directive.

- Perform pre-compliance testing. Test the device under real-world EMI conditions to identify potential weaknesses.

- Work with an EMC laboratory. Partnering with an accredited test laboratory ensures that the device meets all regulatory requirements.

- Document all test results. Maintaining detailed test reports facilitates a smoother certification process and helps resolve potential compliance questions.

A common misconception among manufacturers is that general EMC compliance guarantees OIML approval. However, OIML evaluates devices based on their ability to maintain accurate measurements under electromagnetic stress, rather than their overall emissions or immunity performance. Addressing compliance at the design stage rather than after a failed test is key to avoiding delays and costly modifications.

Conclusion

EMC compliance is not just a regulatory requirement – it is fundamental to ensuring that measuring instruments provide accurate and reliable data in real-world conditions. As electromagnetic environments become increasingly complex, proactive EMC design is essential to prevent interference that can compromise measurement accuracy, lead to compliance failures, and cause delays in market approval.

By incorporating shielding, grounding, circuit layout optimization, and pre-compliance testing early in the development process, manufacturers can reduce the risk of costly redesigns and improve their chances of passing conformity assessment on the first attempt. Understanding the nuances of OIML-specific EMC requirements, which focus on maintaining measurement accuracy under EMI exposure, is also key to navigating the approval process successfully.

For those working through EMC challenges in legal metrology, staying informed about best practices, testing methodologies, and regulatory updates can help streamline compliance efforts. If you have further questions about the technical aspects of EMC testing, conformity assessment, or best practices for ensuring compliance, NMi’s expertise in legal metrology testing and certification serves as a valuable resource.